Latest News

New Approach Methodologies (NAMs)

The EMA, FDA, and US EPA are looking to reduce unnecessary animal testing, which involves replacing in vivo animal studies with in vitro and in silico methods to determine the toxicity of a substance.

SAXOCON welcomes this focus on enhancing animal well-being while maintaining high standards for determining the safety of chemical compounds. These new methods are the future of toxicological risk assessment, a future that we have been at the forefront of for over 8 years.

Future-proof your development processes with our cutting-edge modelling and let our experts guide you to the best strategy for using New Approach Methodologies (NAMs).

Contact us for more information.

Read more about our services here:

Medical Devices

Pharmaceuticals

Chemicals

FDA CGMP Requirements Incorporating ISO 13485

We are on the verge to merge. Things in the regulatory space for medical device manufacturers are about to get easier.

In a new proposal on Quality System Regulation Amendments for Medical Devices, The FDA has decided to harmonize their GMP requirement for medical devices by incorporating the QMS requirements from ISO 13485.

This harmonization will ease the regulatory burden on medical device manufacturers selling on both sides of the Atlantic. Medical Device Manufacturers and their suppliers and subcontractors that are ISO 13485 certified will no longer have to comply with a different set of standards for approval in the USA.

SAXOCON is ISO 13485 certified and can help you with your QMS, which helps you comply with all relevant regulations but also gives you a better understanding of your supply chain and manufacturing processes.

Read more about how we can help you here.

Food Contact Materials Biosafety

Packaging is not the first thing we think of when we think of food. However, the biosafety of the materials used in food packaging impact the food contained within. So, it is essential to understand the health and safety consequences of the packaging. For more information, read this EFSA article on food contact materials regulations.

All food packaging materials, known as food contact materials, must be evaluated for their potential for transferring harmful substances to food. Every supplier in the supply chain for food contact materials is responsible for demonstrating compliance with all applicable rules and regulations regarding food contact materials.

SAXOCON can help you ensure that your materials comply with EU and FDA rules concerning food contact materials.

Check out how we can help here.

Biosafety and In-Vitro Diagnostics

Do you manufacture in-vitro diagnostic medical devices?

If so, you will need a CE Mark certificate to market them in the EU. A CE certificate verifies the biosafety of your products and that they perform as intended. Regulations such as (EU) 2017/746 (IVDR) Annex I set general biosafety and performance requirements for designing and verifying in-vitro diagnostic medical devices. Our experts have the knowledge and experience to help you plan, test, and document compliance with all regulatory requirements and get your product to market.

Check out how we can help here.

Material Readiness and Marketability

To know your materials is the beginning of wisdom.

One key aspect of manufacturing is materials screening. Proper biosafety and sourcing require having full transparency about the physical and chemical information associated with your materials throughout your supply chain to help mitigate risk, reduce unexpected events, and keep regulators happy.

Manufacturers of medical devices, pharmaceuticals or combination products operating in the EU must ensure the quality and safety of the materials used in their products before marketing them. Early and robust materials selection helps meet regulatory requirements, mitigate risk, and get your products to market quickly.

Check out how we can help here, here, here, here, and here.

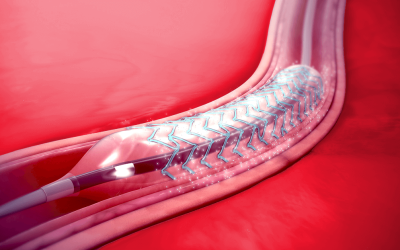

Medical Implant Biosafety

Ensuring the biosafety of your medical implants is necessary for getting them in compliance with relevant regulations.

Medical implants come into intimate contact with the human body for periods lasting from a few hours to permanently. As such, they are subject to strict regulations regarding their safety. Manufacturers of medical implants need to apply for a CE Mark certificate if they are to be sold and used in the EU. A CE certificate verifies that a product is safe and performs as intended. The ISO 10993-1 standard describes the requirements for evaluating and testing the biological safety of all constituent materials in a medical device product.

SAXOCON has the expertise to help you get your implants compliant and certified for sale in the EU.

Read more about our services here.

Workplace Air Quality

Are you a manufacturer? Do you know what particles your workers are exposed to in your working environment? Whether it’s additive manufacturing, assembly, welding or any other process that produces dust or fumes, your workers are being exposed to particles. Mitigating any health concerns for your workers requires understanding how many and the nature of the particles produced. Usually, this understanding requires long-term comprehensive studies to assess potential toxicological exposure.

SAXOCON can help you quickly understand the potential risks involved in your manufacturing processes by coming to you and, using our novel tool, the SAXOCON Impactor, sampling particles from the air in your workplace directly onto electron microscopy grids. This process greatly accelerates the assessment process so you and your workers can have peace of mind.

Check out how we can help here.

Reusable Medical Device Safety

Do you manufacture reusable medical devices?

If so, your products are likely used in medical facilities around the world.

In the EU, manufacturers wanting to sell reusable medical devices must ensure that their cleaning, disinfection, and sterilisation procedures are validated.

SAXOCON has the expertise to help you get your procedures into compliance with all relevant guidelines, such as AAMI TIR12 and ISO 17665, and keep your products on the market or get your new products approved quickly.

White Paper – Medical Devices and Particulates

Medical devices are often vital for a patient’s well-being and must therefore be safe and should definitely not worsen their condition. However, there is a high risk of particulate contamination for intravenous and infusion medical devices that can cause health issues such as inflammation, irritation or even blood clots.

Several factors determine the level of risk a particle presents, with particle size, shape, and composition determining the associated health risks. Once found, particles can be analysed using automated microscopy, computational counting methods, and surface analysis of their physical, topographical, and morphological properties.

According to international standards, these analyses should be performed using an, at minimum, ISO Class N5 certified laboratory to minimise potential contamination. Likewise, it is necessary to conduct these analyses with the utmost precision and concentration.

SAXOCON offers a tailor-made analysis for your medical devices with a clean ISO Class N2 laboratory – which is an even higher standard than the minimum required ISO Class N5. We conduct all required tests following ISO 8536-4, USP 788, and other relevant guidelines. Furthermore, SAXOCON conducts a toxicity analysis of any particles found in your products.

By filling out the form below, you can download our white paper about medical devices and particulates and the consequences for your testing and manufacturing processes.

EFSA Deadline for Food Enzyme Documentation Fast Approaching

Are you ready for the upcoming requirements for submission and approval of your food enzymes?

In March 2020, EFSA announced changes in how food enzymes compiled in joint dossiers will be evaluated. The deadline for meeting the new requirements is 21 April 2022. If you currently have included your food enzymes in a joint dossier, you will need to conduct an updated toxicological study to ensure compliance. SAXOCON’s highly skilled toxicologists can help you plan for the upcoming deadline and test and document the safety of your food enzymes.

Joint dossiers create several challenges and data gaps in currently submitted documentation, which is why EFSA is now requiring that enzyme applicants send a company-specific comprehensive data package. The updated requirements require conducting a toxicological assessment in accordance with regulatory guidelines.

Until now, it has been possible for the producers of food enzymes to group individual food enzymes under one umbrella application, provided the enzymes had the same catalytic activities, were manufactured using a similar process, and originated from the same organism. However, due to confidentiality issues, the current procedure has led to a lack of specific information regarding aspects like the production strain or the chemical composition of each food enzyme.

EFSA provides detailed information about these changes in this article.

SAXOCON can help you prepare for these regulatory changes.

Read more about how we can help here.

Chemically Non-compliant Products Sold Online in EU

A recent report by the ECHA found that over half the products sold online in the EU were non-compliant with one or more EU requirements with regard to chemicals. These findings resulted in more than 5000 enforcement actions by national authorities.

As a product manufacturer, this is an entirely avoidable problem. With the proper understanding and traceability of the chemicals present in your products and the suppliers of these materials, you can avoid running afoul of regulators.

Don’t get caught with your chemical pants down at the next inspection. SAXOCON has the expertise to help you ensure that your products are compliant with all relevant regulations.

Nitrosamine Impurities

Are you a pharmaceutical manufacturer? Do you know whether your products contain nitrosamine impurities and, if so, whether they are below the thresholds established by the various regulatory agencies?

SAXOCON has the expertise and services necessary to help you to fill in the gaps in your supply chain information and assess the impact on your drug substances and products.

Nitrosamines are highly toxic compounds. Some are considered to be even more carcinogenic than currently established thresholds and are subject to strict regulations in both the EU and the US.

Check out how we can help here.