Latest News

Ensure Product Safety through Rigorous Particulate Contamination Testing

Pharmaceutical and medical device manufacturers need to ensure the safety of the materials used in their products. Particulate contamination is a risk in production facilities. Good Manufacturing Practice (GMP) and proper risk management require the identification of root causes and evaluating the impact that particulate matter findings can have on product safety. Understanding the risk as quickly as possible is crucial when deciding whether to release or recall affected product batches.

There are several international standards governing particulate testing and it is a daunting task to know where to start to ensure the safety of your products. SAXOCON has the facilities and expertise to quickly process and assess unexpected particulate findings and provide a mitigation strategy. Once completed, we send a comprehensive report of the results.

Why Particulate Contamination Testing Matters:

- Patient Safety: Contaminants can cause severe adverse reactions in patients, leading to complications or even life-threatening situations.

- Regulatory Compliance: Strict guidelines from agencies like the FDA and EMA mandate rigorous testing to ensure products meet safety standards.

- Product Integrity: Maintaining the highest levels of purity ensures the efficacy and reliability of medical devices and pharmaceuticals.

- Brand Reputation: Consistent quality control fosters trust and loyalty among healthcare professionals and patients.

Check out how we can help here and here.

New Regulations for Silicone

Last fall, the European Chemicals Agency (ECHA) won a decisive judgement at the European Court of Justice. This judgement allows the ECHA to classify silicone oligomers, specifically D4, D5, and D6 siloxanes, as Persistent Bioaccumulative and Toxic substances (PBT), Very Persistent and Very Bioaccumulative substances (vPvB), and as suspected to be toxic to human reproduction.

On 16 May 2024, the European Commission approved the new silicone regulations under REACH. Therefore, if you use silicone in the medical devices you produce, you need to be aware that they are now subject to scrutiny by the ECHA and classified as harmful.

Silicone oligomers are an unavoidable result of silicone production processes and must be accounted for before any medical device containing silicone can be approved for sale in the EU.

At SAXOCON, we have the expertise to properly risk-assess the silicone in your products to determine if it meets these new requirements. This new regulatory regime has far-reaching consequences for new and existing products. Contact us to find out how we can help you determine the compliance of your silicone products.

We have several services to help risk assess your products, including:

Materials screening and selection

Surface characterisation

Device-drug safety

CE Certification of Implants

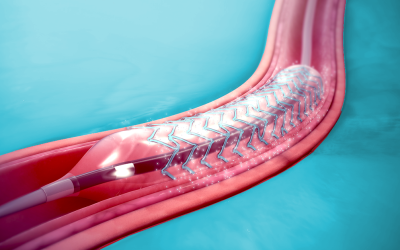

Medical device manufacturers must ensure the biosafety of their medical implant products to comply with relevant regulations.

Medical implants have intimate contact with the human body for durations lasting a few hours to permanently. As such, they are subject to strict regulations regarding their safety. To sell an implant in the EU, it must have a CE Mark certificate, which verifies that a product is safe and performs as intended. The ISO 10993-1 standard describes the requirements for evaluating and testing the biological safety of all the constituent materials in a medical device product.

Ensuring compliance is no easy task and requires deep knowledge of the factors affecting product safety. From raw material selection to potential impurities introduced during production or from the packaging of the final finished product, there are several ways that implant safety can be compromised and which must be considered.

Our experts can help you ensure implant safety and get them compliant and certified for sale in the EU.

Read more about our services here.

ISO 13485, GMP, MDR, and Supply Chain Confidence

Whether you are a pharmaceutical or medical device manufacturer, you need to comply with several layers of guidelines and regulations to bring your products to market and keep them there. Having suppliers you can trust is crucial to your ability to concentrate on making your products the best they can be. SAXOCON is ISO 13485 certified, allowing us to function as a plug-and-play partner to help you develop high-quality products.

In the EU, Pharmaceutical manufacturers must adhere to Good manufacturing practice (GMP) guidelines. GMP compliance ensures that medical products are produced consistently and controlled for quality to ensure their safety and effectiveness. These guidelines are not prescriptive, so the individual manufacturer is responsible for designing a quality system that ensures product quality, from raw materials to final finished product.

EU Regulation (EC) 2017/745 (MDR) and US 21 CFR 820 cover medical devices and require manufacturers to demonstrate that their selected critical suppliers, contractors, and consultants meet all specified requirements, including quality requirements. These regulations hold manufacturers fully responsible for all outsourced processes. Fulfilling this obligation requires understanding and monitoring every aspect of the supply chain, including the materials used, the impacts manufacturing processes can have on final products, and whether any impurities found in the materials used can affect end users. The state-of-the-art practice for medical device manufacturers in the EU and US is adherence to the quality management systems standard from ISO 13485:2016.

As a manufacturer, having confidence in your suppliers lets you focus on making your manufacturing processes and products safe and compliant so they can be approved and ready for market as quickly as possible. Since 2021, SAXOCON has been ISO 13485 certified, allowing us to serve as a critical supplier of toxicological evaluation services. Our quality management system ensures we have the right resources, competencies, procedures, and processes to provide consistent and quality-controlled services. Using us as a supplier of high-quality toxicological services gives you peace of mind and one less thing to worry about at your next audit.

For us as a consultancy, ISO 13485 certification is our version of GMP. Getting certified is not a one-off event, and our processes are audited regularly to ensure they remain compliant. Therefore, we are committed to continually investing in, developing, and improving our quality management system.

Learn more about how our certified services can support your business below:

Medical device manufacturers

Pharmaceutical manufacturers

Starting Up Right

Being part of a startup can be an exhilarating experience; working together to create new and exciting products, combining the talents and vision of your co-workers, and riding on the wave of enthusiasm make the blood, sweat, and tears worth it. But just when you think you are ready to go to market, you fall at the final hurdle: approval denied by the relevant regulatory institution. What now? Do you have to start over? Maybe, maybe not.

SAXOCON A/S was founded in 2013 as a spinout/startup from DTU, so we have lived through the challenges associated with building a new business. Our startup experience, combined with our deep understanding of the regulatory space, allows us to get you and your idea on the right regulatory path from the start. Free your resources up to concentrate on designing your product, and let us ensure that it is compliant and safe.

Contact us to find out more about how we can help.

Unexpected Findings in Production

Pharmaceutical and medical device manufacturers and materials suppliers must ensure their products are not shedding harmful particles. Unexpected particulate findings during production are a risk that all manufacturers face.

Sudden, unexpected findings of particulate matter in or in contact with products can occur in production facilities. Good Manufacturing Practice (GMP) and proper risk management of product quality require identifying root causes and evaluating the impact of such findings on biosafety. This knowledge is crucial to deciding whether to release or recall affected products.

A quick response is necessary when a finding occurs. Your production can be put on hold while identifying the affected lots, and then the hard work of figuring out the type and extent of the problem begins.

SAXOCON has the in-house expertise and experience to help you quickly assess, process, and mitigate any unexpected findings.

Read more about how we can help you here.

Contamination in Pharmaceutical Production

One of the key responsibilities of pharmaceutical manufacturers is to test the materials used in the manufacturing process to ensure safety and compliance and keep production running smoothly. At SAXOCON, we have the in-house expertise and experience to help you quickly assess and test your production components and materials.

One of the greatest risks manufacturers of pharmaceuticals face is that a product gets contaminated during the manufacturing process. Such an incident can stop production until the contamination source is located and eliminated or, in the worst-case scenario, result in a product recall.

Contamination in pharmaceutical production can occur at every stage of the production process, from sourcing materials to processing the materials to filling the final drug product. Pharmaceutical manufacturers and CDMO facilities can contain thousands of components and materials that can come into contact with the drug products being produced (PCMs).

Good Manufacturing Practice (GMP) provides no guidance on what or how to test PCMs. This is where the BioPhorum Operation Group (BPOG) recommendations and the United States Pharmacopeia – National Formulary (USP) guidelines can help. The BPOG recommendations and USP chapters 665 and 1665 provide guidance about what to test and how to test it. Proper testing and a transparent supply chain with fully identified materials can help reduce the number of unexpected findings and ensure your products are safe, reliable, and compliant.

Check out our services to see how we can help you:

Equipment Safety

Cleaning Validation

Unexpected Findings

Imupurities Testing

BPOG, USP 665 and 1665 and You

In May this year, US Pharmacopeia (USP) chapter 665 will come into effect, and mandatory testing for extractables and leachables (E&L) studies of plastic single-use systems are now required. Moreover, the BioPhorum Operations Group (BPOG) industry collaboration has published protocols that provide comprehensive data, which allows manufacturers to compare materials from multiple suppliers. SAXOCON can help your company ensure that your materials are compliant and that your suppliers provide high-quality, traceable products.

Pharmaceutical manufacturers have increased their use of single-use systems (SUS) to lower costs and increase efficiency. SUS substitutes polymers for glass and stainless steel. Polymers have many advantages but require extra vigilance when selecting materials and vendors.

As polymers present a greater leachables risk, they are subject to greater regulatory scrutiny. These regulations specify the limits that leachables must be under but do not provide guidance about testing.

The USP 665 standard covers the characterisation and qualification of single-use technology (SUT) using plastic components and systems for manufacturing pharmaceutical drug products and biopharmaceutical drug substances and products. One of the central concepts of testing per USP 665 involves exposing materials to temperature extremes and solvents.

USP 1665 provides guidance on applying USP Chapter 665, including suggested risk assessment approaches and how to implement them.

Check out our services here:

Equipment Safety

Impurities Testing

Materials Screening

FDA Recognizes ISO 10993:17

The FDA has just recognized the recently updated ISO 10993 Part 17 standard covering the toxicological risk assessment of medical device constituents. Apart from a few exceptions, the FDA recognized the standard for its relevance and scientific and technical merit.

ISO 10993-17:2023 introduces some new concepts for toxicological risk assessments, such as toxicological screening limits (TSLs) and maximum estimated exposure dose (EEDmax), which will improve accuracy and reliability. These significant changes impact medical device manufacturers when preparing to introduce or update products.

As our CTO, Carsten Baun Senholt, is a member of the international technical committee TC 194, which designed the new standard, we are well positioned to offer fully compliant, certified QMS and toxicological risk assessments.

Read more about how we can help you with ISO 10993-17 compliance:

Biological Evaluation Report

Safely Manage Change

Major Change: EU Can Classify Silicone as a Restricted Substance

Do you use silicone in the medical devices you produce? If so, you need to be aware that the European Chemicals Agency (ECHA) can now classify silicone oligomers, specifically D4, D5, and D6 siloxanes, as Persistent Bioaccumulative and Toxic substances (PBT), Very Persistent and Very Bioaccumulative substances (vPvB), and suspected to be toxic to human reproduction after a decisive ruling by the European Court of Justice.

Silicone oligomers are an unavoidable result of the production processes for silicone that must now be accounted for before a medical device containing silicone can be approved for sale in the EU.

At SAXOCON, we have the expertise to properly risk assess the silicone in your products to determine if it meets the new requirements. This ruling marks a change that has far-reaching consequences for new and existing products. Contact us to find out how we can help you determine how compliant your silicone products are.

We have several services to help risk assess your products, including:

Materials screening and selection

Surface characterisation

Device-drug safety

Materials Screening

Medical device manufacturers need to screen the materials used in their products. Proper biosafety and sourcing require having full transparency about the physical and chemical information associated with the materials throughout the supply chain. Knowing what is in the materials you use helps mitigate risk, reduces unexpected findings, and keeps regulators happy.

To operate in the EU, medical device manufacturers must ensure the quality and safety of the materials used in their products before they can bring them to market. Early and robust materials selection helps meet regulatory requirements, mitigate risk, and get your products to market quickly.

SAXOCON has several services to help you understand your materials and get compliant with all relevant regulations:

Materials Screening

Primary Packaging Safety

Safe Drug-delivery Devices

Surface Characterisation

Safe Food Contact Materials

Nitrosamine Impurities in Primary Packaging

Pharmaceutical manufacturers need to know whether their products contain nitrosamine impurities and, if so, whether they are below the thresholds established by various regulatory agencies.

Nitrosamines are highly toxic compounds, with some considered even more carcinogenic than currently established thresholds suggest and are, therefore, subject to strict regulations in both the EU and the US.

The introduction of nitrosamine impurities can occur at any stage of the supply chain, from raw material processing to the manufacturing process to appearing as leachables from packaging and storage.

The EMA and FDA are shifting their focus to packaging materials as a potential source of nitrosamine impurities. This shift in focus means that manufacturers need to know what is in their packaging materials, whether they can leach nitrosamines, and how to mitigate potential problems.

Our services, designed and run by our team of experts, can help you fill in the gaps in your supply chain information and assess your packaging and storage processes for the presence of nitrosamines.

Check out how we can help here.